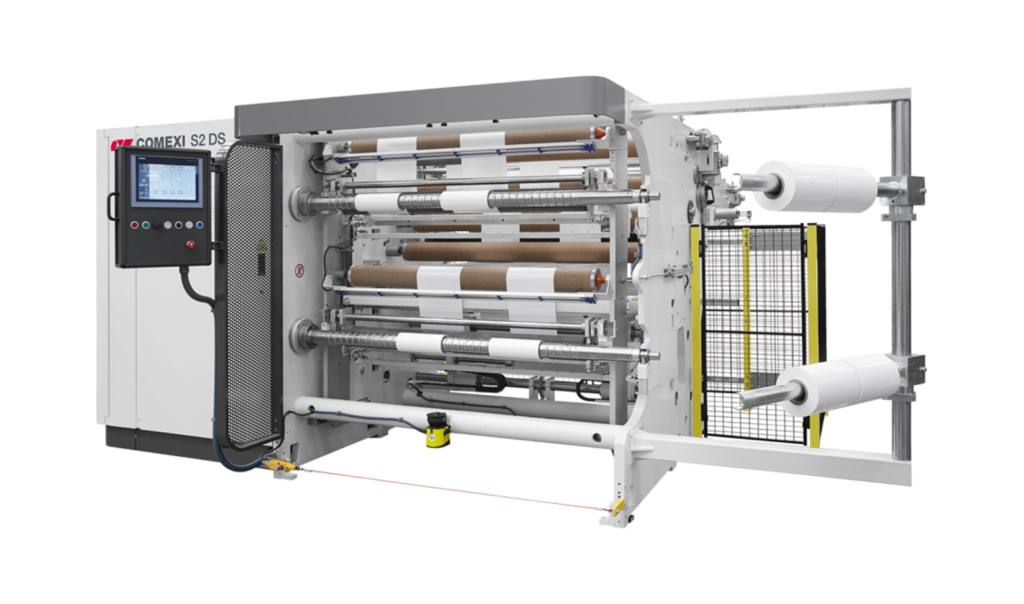

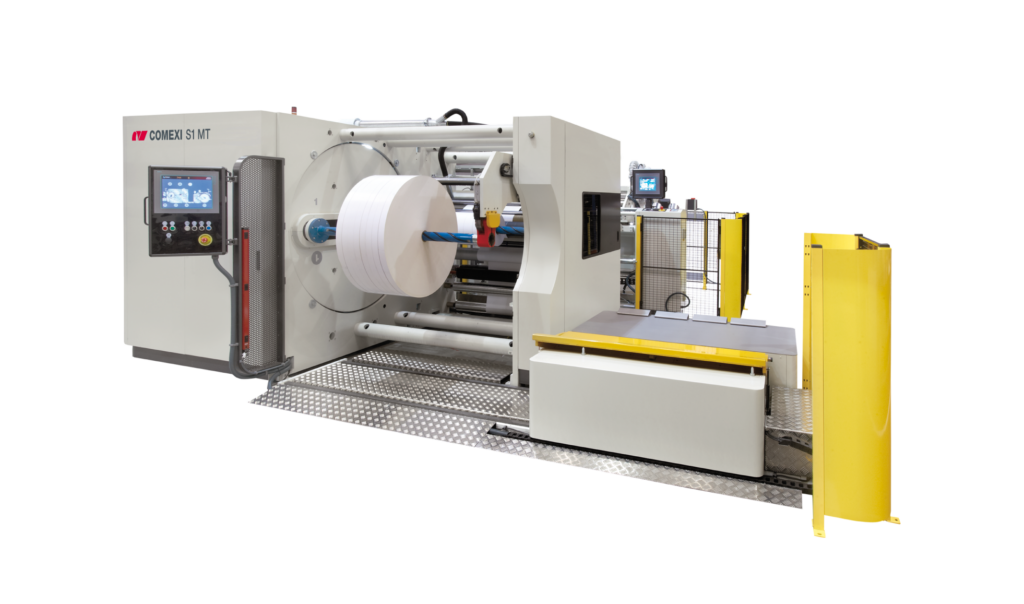

SLITTING, LASER & REEL HANDLING

Discover the power of final converting processes. Our high-quality slitters ensure maximum productivity and superior results. Ready to experience the best in converting efficiency? Try our top-notch slitters today.

Laser

ADDED VALUE FOR YOUR PACKAGING WITH LASER APPLICATIONS

| Laser Power | 40 / 100 / 300 W |

| Laser heads | from 2 to 10 |

| Wavelength | 10.2 μm |

| Spot Size | from 50 to 500 μm |

| Laser source | Co2 |

| Maximum speed | 700 m/min |

| Cooling system | Air / Water |

| Laser Power | 40 / 100 / 300 W |

| Laser heads | from 2 to 10 |

| Wavelength | 10.2 μm |

| Spot Size | from 50 to 500 μm |

| Laser source | Co2 |

| Maximum speed | 700 m/min |

| Cooling system | Air / Water |

Complete your printing process

For the perfect integration of the whole converting process, Comexi offers solutions in , slitting, and laser.

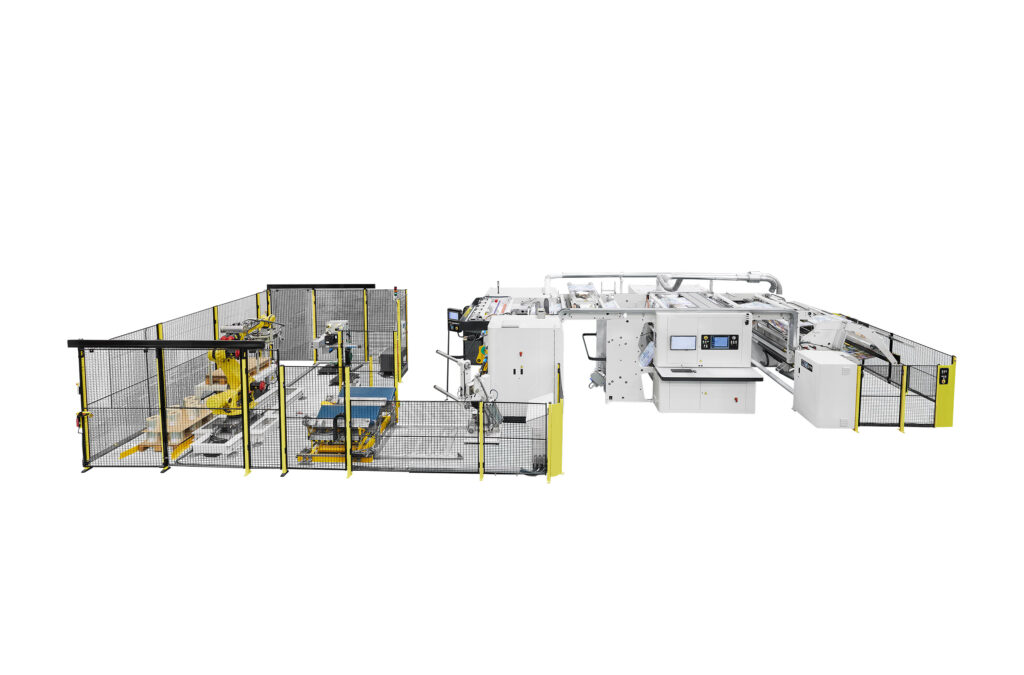

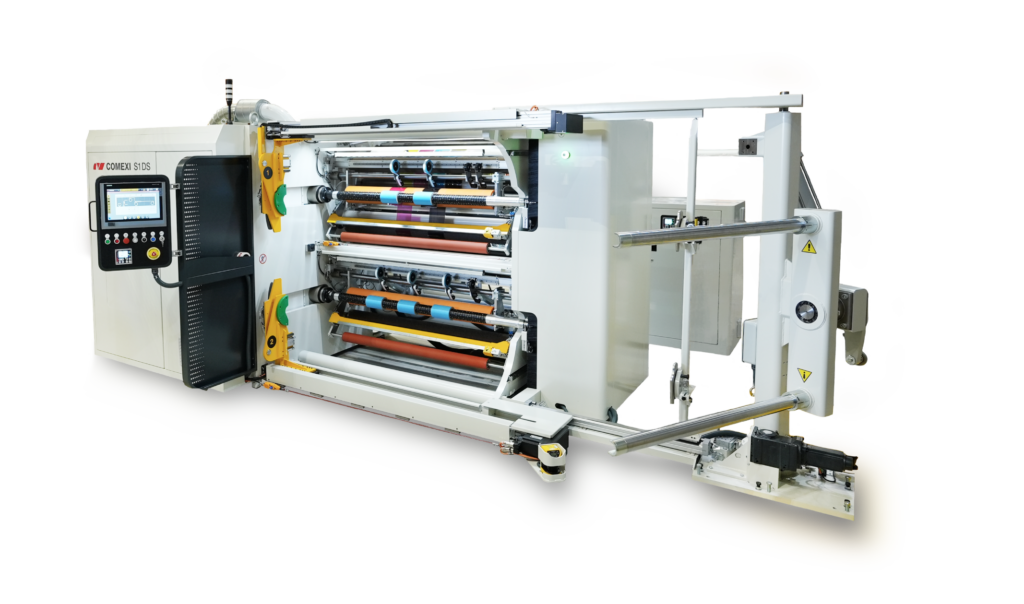

Slitting finishes the process to offer a smaller and error-free coil. Comexi slitters are widely recognized for their high quality and performance.

- Maximum productivity: shorter working cycles, faster changeovers, savings in labor and energy costs. Speeds up to 1000 m/min.

- Reliability: quality of the final application assured. Avoids unexpected stops.

- Versatile: suitable for multiple materials and applications: different types of flexible plastics, paper, cardboard, … Materials ranging from 7 to 620 microns.

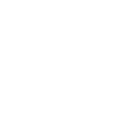

Enhancing Converter Efficiency: Reel Handling Solutions

Reel handling solutions are invaluable for converters in the packaging industry. These specialized tools and automated equipment streamline the handling, transportation, and storage of reels, optimizing efficiency and reducing manual labor. It is also key to traceability and to avoid human mistakes.